This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

RFID Inlay Sheet

CATEGORIES

Featured products

RFID Solutions For Retail

RFID Protocol: EPC Class1 Gen2, ISO18000-6C Frequency: US (902-928MHZ), EU…

RFID Retail Tracking

RFID Protocol: EPC Class1 Gen2, ISO18000-6C Frequency: US(902-928MHZ), EU(865-868MHZ) IC…

RFID Tags Bracelet

Fujian RFID Solutions Co., Ltd. is a leading RFID technology…

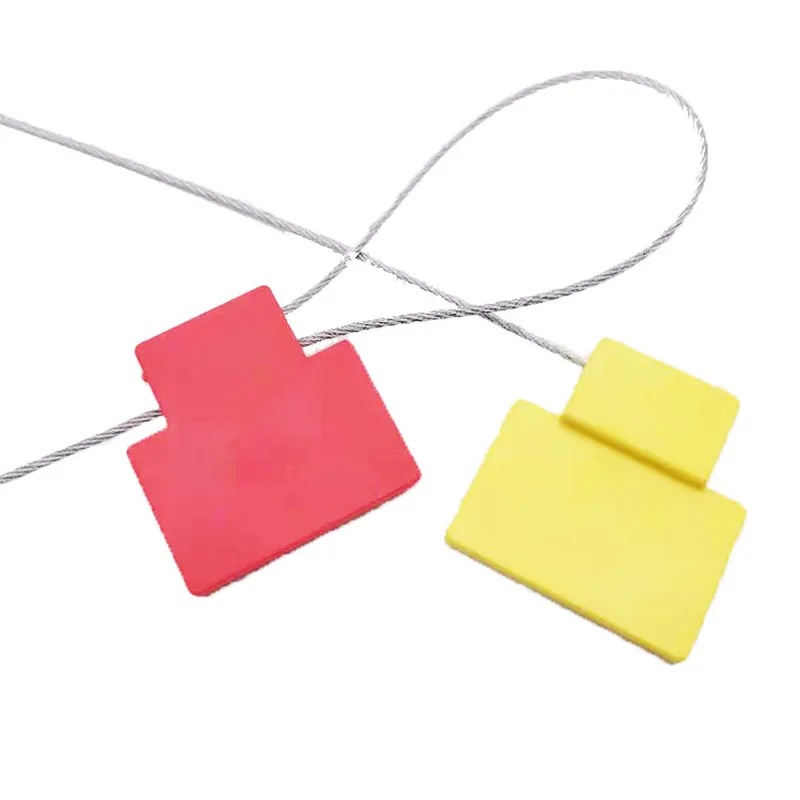

RFID Cable Seal

The rfid cable seal is a tamper-proof, one-time design used…

Recent News

Short Description:

RFID CARDS products use an RFID inlay sheet, which can be customized for antenna, layout, and frequency. The inlay sheet is made using ultrasonic technology, inexpensive pre-winding technique, and flip-chip technology. It can be made in various shapes and sizes, and can be fused with PVC sheets and coated PVC overlays. It offers high read distance and can combine different chip technologies.

Share us:

Product Detail

RFID CARDS products utilize an RFID inlay sheet. Customization is possible for the antenna, layout, and frequency. Cooper winding will improve the stability of the RFID signal.

The essential component of an RFID card is the RFID inlay sheet, also known as the contactless card inlay or RFID card prelim. This plastic card insert is made using three technologies: 1. Ultrasonic technology operates at the highest efficiency. 2. Pre-winding technique is inexpensive. 3. Flip-chip technology has a thinnest thickness and a flat surface.

Parameter

- Thickness: Low frequency (125KHz) 0.35mm, 0.4mm, 0.45mm, 0.5mm or custom-made

- High frequency(13.56MHz) 0.5mm, 0.55mm, 0.6mm or custom-made

- Common layout: 2*5, 3*5, 3*7, 3*8, 4*4, 4*5, 4*6, 4*8, 4*10, 5*5, 6*8, etc.

- Number of chips: 10, 15, 21, 24, 16, 20, 24, 32, 40, 25, 48, etc.

- Antenna shape: Round or Oval

- Method of production: hot press lamination, using PVC or PET materials.

| Item | A4 size 2*5 layout RFID Inlay Sheet 13.56MHz 1K Chip Inlay Sheet Prelam For Smart Card |

| Frequency | 13.56MHz |

| Protocol | ISO14443A |

| Reading Distance | depend on the Reader and Chip |

| Certification | ISO9001,ISO14001,CE etc |

| Antenna shape | Round, Square, rectangle |

| encapsulated format | COB – default.

MOA4, 6,8 (Module) Module price and prelim with rfid tags price are different, please contact our sales team to get the latest price. |

| Antenna | cooper/aluminum |

| Available Colors | Transparent or White |

| Printing | logo printing Acceptable |

| Technical support | Chip Encoding |

| Woking times: | >100000 times |

| Temperature | -10°C to +50°C |

| Operating humidity | ≤80% |

| Sample Availability | Free samples are available upon request |

| Packaging | 200sheet/carton, or per your requests |

| Application | Mainly for Smart card factory |

Features

- Easily make RFID chip cards without specialized machines.

- Can be fused with PVC sheets and coated PVC overlays.

- Various RFID IC options (HF/LF) are available for alternating use.

- Different kinds of materials, including PVC, and PETG.

- High read distance optimized for each chip.

- Possibility to combine two different chip technologies in one card.

- Various chip layouts available: 2×5, 3×6, 3×7, 3×8, 3×10, 4×8, others available on request.

Packing & Delivery

For A4 size 2*5 layout RFID Inlay Sheet 13.56MHz 1K Chip Inlay Sheet Prelam For Smart Card packaging

200 pieces per box and 20 boxes per carton

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/uploads/2024/04/logo.webp)

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/plugins/gdpr-cookie-compliance/dist/images/gdpr-logo.png)