This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

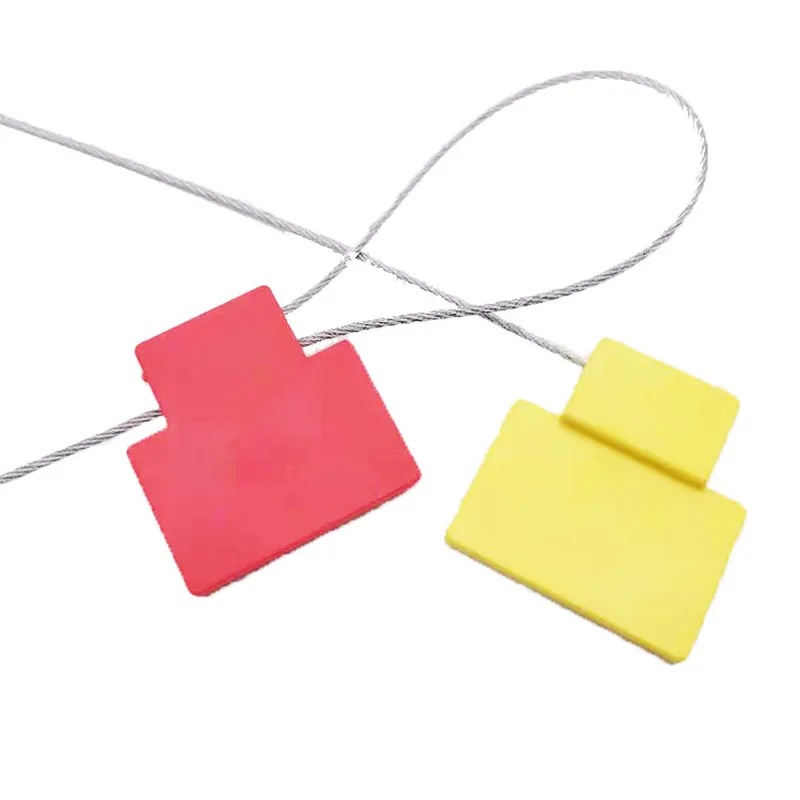

RFID Cable Seal

CATEGORIES

Featured products

RFID Seal Tag

RFID Seal Tag cable ties are made of ABS material…

IC rfid Reader

The RS60C is a high-performance 13.56Mhz RFID IC RFID Reader…

Retail RFID Tags For Texitle

Retail RFID Tags For Texitle are used in hotels, hospitals,…

Portable RFID Reader

The PT160 Portable RFID Reader is a reliable and portable…

Recent News

Short Description:

The rfid cable seal is a tamper-proof, one-time design used to secure tubes or loose goods, offering unique ID numbers for asset management, item tracking, and material workflow control. It integrates NFC technology, making it easier to read information on a phone. RFID tags can be attached to wires, cables, or strapping, improving cable management efficiency and accuracy. Applications include power, communications, and rail travel.

Share us:

Product Detail

rfid cable seal may be used to secure tubes or loose goods and offer unique ID numbers for asset management, item tracking, and material workflow control. Its one-time design makes it tamper-proof, increasing security. The tags also integrate NFC technology, making it easier to read information on a phone.

RFID cable tags may be attached to wires, cables, or strapping using cable ties or straps to identify audio/video cables, power and ground cables, data center wires, cable harnesses, etc. Cable management is much more efficient and accurate using this software.

Parameter

| Product name | High-Security RFID Cable Seal |

| Material | ABS plastic & galvanized steel |

| Size | 38x26mm, 40x28mm, 44x28mm, 45x44mm, 48x40mm,56x56mm, 60x28mm, 80x30mm |

| Color | Red, White, Back, Yellow, Blue or any customized color |

| Working Frequency | 13.56MHz/915MHZ |

| Chip | NXP Ntag 213/ Impinj MR6-P or Customized |

| Chip protocol | ISO14443A / ISO18000-6C |

| Memory | 1024Bit |

| Reading Distance | 0-400mm (Depending on the type of RFID Reader) |

| Working Temperature | -40℃~100℃ |

| Tensible Force | more than 3000N |

| Installation Method | Pull tight by hand, locking range is adjustable |

| Application | use in Posting Parcel, Container, Tanker, Aircraft, Bank, Customs, etc |

| Printing | Serial numbers, Letters, Logos, Bar codes, and simple images are available by laser printing or Hot Stamping |

| Standard Packaging | 50PCS/Bag , 1000PCS/CTN, 17G/PCS |

Application scenarios

- Cable management: Power, communications, and rail travel have many cables, making management challenging. Radiofrequency identification cable sealing technique improves cable management efficiency and intelligence.

- Cable theft prevention: Cable seals with RFID tags can check cable status in real-time during installation. The device may warn instantly if the cable is unlawfully dismantled or transferred to avoid theft.

- Cable maintenance: RFID technology tracks cable usage and repair in real-time. To maintain cable safety, the system may automatically recall when the cable breaks or needs repair.

Advantages and characteristics

- Smart cable management: RFID technology improves cable management efficiency.

- Cable sealing with RFID tags provide real-time monitoring of cable status to guarantee safety.

- Easy to use: The RFID reader reads and writes RFID tags fast.

- Efficient and convenient: RFID technology instantly locates cables, saving time and money.

- High security: RFID tags’ unique codes prevent cable theft and manipulation.

Implementation suggestions

To guarantee system stability and dependability, use RFID tags and readers based on real demands.

Create a comprehensive database: Create a comprehensive cable database to store and manage data.

Provide realistic operational procedures: Establish suitable operational procedures to properly deploy and operate RFID cable sealing technology.

Maintain and upgrade the system regularly: Regularly maintain and upgrade the RFID system to guarantee data correctness and system functionality.

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/uploads/2024/04/logo.webp)

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/plugins/gdpr-cookie-compliance/dist/images/gdpr-logo.png)