This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

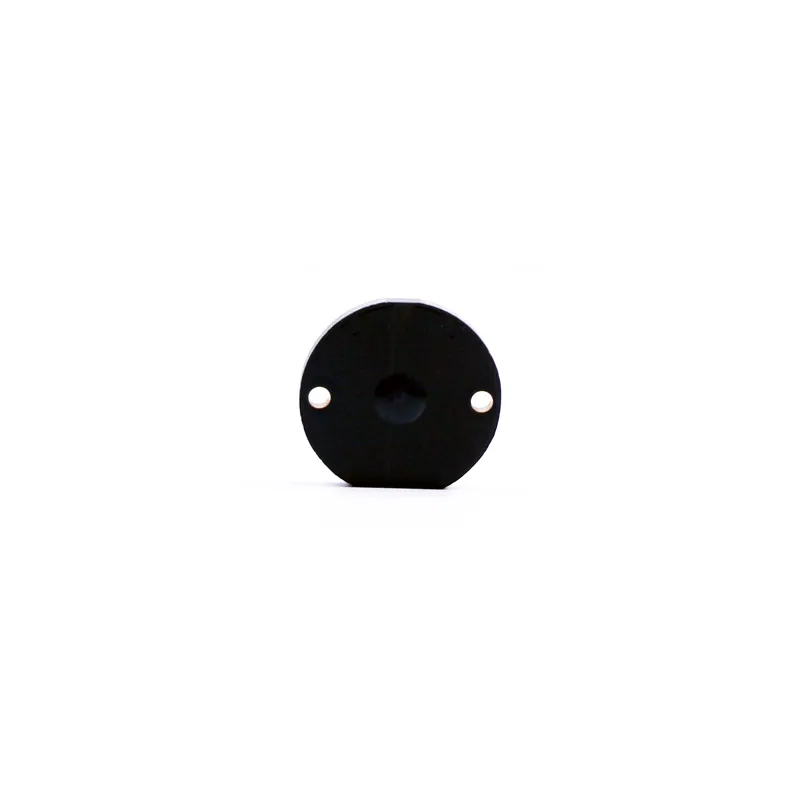

RFID Tag Construction

CATEGORIES

Featured products

RFID Clamshell Card

RFID Clamshell Card made of ABS and PVC/PET materials are…

RFID Tag Bracelet

RFID Tag Bracelets are widely used in various applications, including…

Long Distance UHF Metal Tag

The Long Distance UHF Metal Tag is an RFID tag…

RFID Wrist Tag

The RFID Wrist Tag is a convenient way for hotel…

Recent News

Short Description:

RFID Tag Construction brings modern and efficient solutions to the construction industry by improving management efficiency, construction accuracy and safety.

Share us:

Product Detail

RFID Tag Construction brings modern and efficient solutions to the construction industry by improving management efficiency, construction accuracy and safety.

Application

Construction Management

- Material Management: RFID tags allow for real-time tracking and management of a variety of materials on building sites. RFID tags may be used to swiftly capture the amount, characteristics, and source of items as they enter the site. This information can then be linked to the data in the database to enhance the efficiency of material management and use.

- Equipment Management: RFID tags are used in equipment management to store data such as purchase date, maintenance history, and basic equipment information.

- This facilitates equipment scheduling, maintenance planning, and resource optimization for management.

- Tracking Progress: RFID tags may be used to monitor each part’s progress throughout a building project, ensuring that jobs are finished on schedule.

Safety and Personnel Management

- Personnel Management: To guarantee efficient workflow and increase safety, workers on construction sites may be issued work certificates or wear wristbands with RFID tags to track their locations, work areas, and times of arrival and departure in real time.

- Safety Management: RFID technology may also be used to monitor shelter facilities and safety equipment. For example, staff hard helmets with embedded RFID tags can be automatically programmed to detect when they are being worn.

Prefabricated Component Management

RFID prefabricated parts may save prices while increasing accuracy and efficiency in building. The amount of time and labor required for on-site building is decreased by preassembling and inserting RFID tags in the factory.

Utilize RFID readers to monitor and control prefabricated parts, expedite the assembly process, and use wireless signals to track the location and posture of parts in real time.

Functional Specifications:

RFID Protocol:

EPC Class1 Gen2, ISO18000-6C

Frequency:

(US) 902-928MHz, (EU) 865-868MHz

IC type:

Alien Higgs-3

Memory:

EPC 96bits (Up to 480bits) , USER 512bits, TID64bits

Write Cycles:

100,000 times

Functionality:

Read / Write

Data Retention:

Up to 50 Years

Applicable Surface:

Read Range :

(Fix Reader)

200cm, (US) 902-928MHz

200cm, (EU) 865-868MHz

Read Range :

(Handheld Reader)

120cm, (US) 902-928MHz

120cm, (EU) 865-868MHz

Warranty:

1 Year

Physical Specifications:

Antenna Size:

M16 Screw

Material:

304 Steel

Colour:

Silver gray

Mounting Methods:

Weight:

50g

Environmental Specifications:

IP Rating:

IP68

Storage Temperature:

-40°С to +150°С

Operation Temperature:

-40°С to +100°С

Certifications:

Reach Approved, RoHS Approved,CE Approved

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/uploads/2024/04/logo.webp)

![Rfid Tag manufacturer [Wholesale | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/plugins/gdpr-cookie-compliance/dist/images/gdpr-logo.png)