RFID Tracking Manufacturing

KATEGORI

produk unggulan

RFID Cloth Tag

The 7015H RFID Cloth Tag is designed for textile or…

RFID Retail Tracking

Protokol RFID: EPC Kelas 1 Gen2, Frekuensi ISO18000-6C: AS(902-928MHZ), EU(865-868MHZ) IC…

Mifare Keyfobs

The Mifare two-chip RFID Mifare Keyfobs is a practical, effective,…

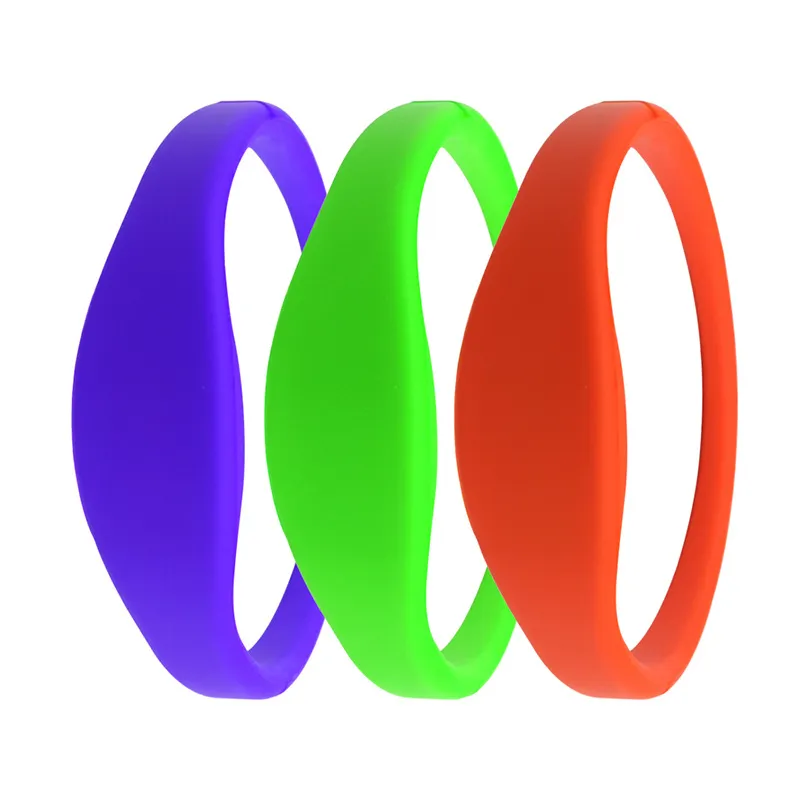

RFID Wristband At Music Festivals

The RFID wristband at music festivals is a powerful, convenient,…

Warta Anyar

Katrangan singkat:

RFID tracking manufacturing uses wireless radio frequency identification technology to track and control objects, machinery, or information in the production process. It offers benefits like multi-tag simultaneous identification, high-speed moving object recognition, and non-contact identification. Applications include automotive, electronic, and pharmaceutical manufacturing, enhancing efficiency and cost-cutting.

Nuduhake kita:

Detail Produk

Using wireless radio frequency identification technology, RFID Tracking Manufacturing aims to accomplish real-time tracking and control of objects, machinery, or information in the manufacturing process. Through an RFID system made up of tags, para maos, and back-end systems, this technology may realise automatic identification, data collecting, and real-time monitoring of goods on the production line.

The objects that require tracking have RFID tags affixed to them during the production process. These tags include associated information and special identifying numbers on them. The reader transmits an activation signal to the tag, turns on the circuit in the tag, and reads the data stored there when the items come into its sensing range. The back-end system receives the data and processes it before storing it and using it for further information tracking and identification.

RFID tracking manufacturing offers several benefits, including multi-tag simultaneous identification, high-speed moving object recognition, and non-contact identification. This implies that the RFID system on the production line can swiftly and accurately read a lot of tag data without the need for human interaction, significantly increasing production efficiency and accuracy. RFID technology can also be used to achieve real-time data analysis and monitoring of the production process, which can assist businesses in streamlining their operations and cutting expenses.

Practically speaking, RFID tracking manufacturing has been applied extensively in a number of manufacturing sectors, including the production of pharmaceuticals, electronics, and cars. RFID technology can be used, for instance, in the automotive manufacturing process to track the flow and assembly of parts to ensure the production line runs smoothly; in the electronic manufacturing process to track component inventory and usage to increase material management efficiency; and in the pharmaceutical manufacturing process to track drug batches and flow to guarantee drug safety and traceability.

Functional Specifications:

Protokol RFID: EPC Kelas 1 Gen2, Frekuensi ISO18000-6C: (AS) 902-928MHz, (EU) 865-868MHz IC type: Alien Higgs-3

Memory: EPC 96bits (Up to 480bits) , USER 512bits, TID 64 bits

Write Cycles: 100,000 times Functionality: Read/write Data Retention: Up to 50 Years Applicable Surface: Metal Surfaces

Read Range :

(Fix Reader)

Read Range :

(Handheld Reader)

Up to 9M – (AS) 902-928MHz, on metal Up to 9M – (EU) 865-868MHz, on metal Up to 5M – (AS) 902-928MHz, on metal Up to 5M – (EU) 865-868MHz, on metal

Warranty: 1 Year

Physical Specification:

Ukuran: 80x20mm, (Hole: D4mm) Thickness: 3.55mm

Materi: FR4 (PCB)

Colour: Black (Red, Biru, Ijo, lan putih) Mounting Methods: Adhesive, Screw

Weight: 12.0g

Dimensions:

MT019 8020U1:

MT019 8020E1:

Environmental Specification:

IP Rating: IP68

Storage Temperature: -40°С to +150°С

Operation Temperature: -40°С to +100°С

Certifications: Reach Approved, RoHS Approved, CE Approved

dhawuh information:

MT019 8020U1 (AS) 902-928MHz,

MT019 8020E1 (EU) 865-868MHz

![Produsen Tag Rfid [Grosir | OEM | ODM]](https://www.fjrfidfactory.com/wp-content/uploads/2024/04/logo.webp)